In Mpumalanga, near the small town of Entokozweni, a once-decommissioned nickel mine is coming back to life. African Rainbow Minerals (ARM) identified more than 35 years of nickel reserves remaining at Nkomati Mine, but reopening required one critical step: draining and treating the floodwater that had filled the mine since closure.

This process demanded an advanced effluent treatment plant capable of handling complex water conditions and meeting strict Water Use License (WUL) regulations. To achieve this, Proxa Water Global, a leader in water treatment solutions, partnered with SBS Tanks to provide the robust storage backbone for the system.

Project Overview: Securing Water Treatment for Mine Restart

Project Overview: Securing Water Treatment for Mine RestartThe scope of the project included the design and construction of three tanks with a total combined capacity of 1.843 million litres:

• ST16/03 (297kL) – Waste Water Tank with 1000g liner.

• ST16/03 (297kL) – Product Tank with XR5 liner for chemical resistance.

• ST31/05 (1.842ML) – Raw Water Tank with 1000g liner.

Together, these tanks formed the core of the effluent treatment plant, designed to pump floodwater from the mine, purify it, and safely return it to the surrounding natural water bodies. By doing so, the mine not only became compliant with environmental regulations but also safeguarded the health of local communities.

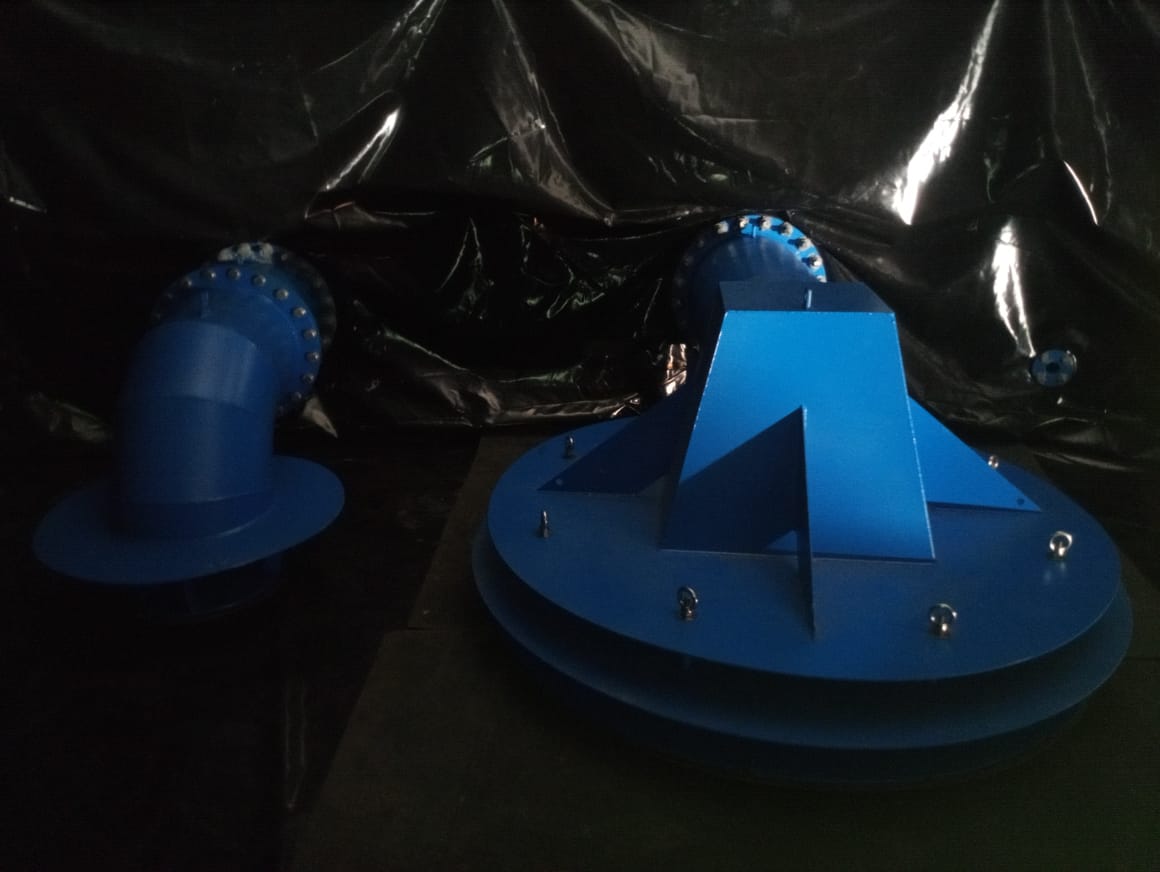

This project was far from standard. The tanks required specialised coatings, XR5 chemical-resistant liners, and engineered roof-mounted nozzles with deflector plates to protect against sludge corrosion. Multiple 450NB feedback suction nozzles, a 500NB backwash system, and custom clarifier cycle nozzles ensured optimal flow and efficiency.

Additional features included:

• Plascoating on all nozzles for chemical resistance.

• Heavy panels designed to withstand the stress of high-flow operations.

• Stainless steel GR3.04 ladders and thermoplastic-coated access hatches for safety and durability.

• These customisations made the SBS tanks a perfect fit for Proxa’s turnkey water treatment solution.

Installation was carried out by two dedicated three-man teams who worked in parallel: both teams team started with the two ST16/03 tanks, and later joined to complete the larger ST31/05 tank.

Proxa was responsible for constructing the ring beams to SBS specifications, with strict QC checks and sign-offs by SBS supervisors. Quality assurance extended through every stage of the build:

• ISO-accredited manufacturing processes.

• Non-Destructive Testing (NDT) of structures and nozzle components.

• On-site inspections signed off jointly by Proxa and SBS.

The result was a fast, efficient build that met both the mine’s timelines and SBS’s world-class quality standards. Didn’t know SBS Tanks operated on mine site? Check our mining range tanks here.

Beyond the technical scope, the project carried significant social value. As part of local regulations, the project incorporated labour from surrounding communities, coordinated through a Community Liaison Officer. This not only created employment during construction but also strengthened ties between the mine and its neighbours.

Environmentally, the tanks ensure that treated effluent water can be safely discharged into nearby rivers, protecting ecosystems and guaranteeing compliance with South African water legislation.

With the mine restarting in the next phase of development, the community of Entokozweni will experience economic revitalisation, with renewed employment opportunities and the promise of long-term stability.

Executives at Proxa and ARM praised the speed of installation, robust design, and professionalism of the SBS Tanks team. The ability to deliver a solution of this scale and complexity on time was highlighted as a key factor in ensuring the water treatment plant could become operational without delay.

This project demonstrates the power of collaboration. By combining Proxa’s turnkey water treatment expertise with SBS Tanks’ engineered storage solutions, the Nkomati Mine has gained a sustainable pathway to restart operations.

For the local community, it represents more than a technical achievement – it is a lifeline for jobs, development, and environmental protection. For SBS Tanks, it is another milestone in delivering reliable, modular, and compliant storage systems that enable mining operations across Africa to thrive responsibly.

*****************************************************************************************

SBS Tanks is Africa’s leading manufacturer and supplier of modular steel panel water storage tanks fitted with an internal liquid storage liner. With offices in Durban, Johannesburg & Cape Town, our factory services all provinces within South Africa and the SADC region. With ISO accreditation (ISO 45001 and ISO 9001) collaborating with a trusted supplier like SBS Tanks, can offer professional advice and a variety of premium tank alternatives to satisfy your various needs.

Contact one of our sales agents today or simply Request a quote here.

© SBS Holdings 2026